The ultimate Engineering, Procurement, Construction

(EPC) Digital Twin 4.0 Platform

PRODUCT DECK

SABER BELGHITH

Founder

Founder

United Arab Emirates | France | Andorra

© Copyright Twintech SLU, 2023

Konnect3D was born out of industry necessity and a great team ambition

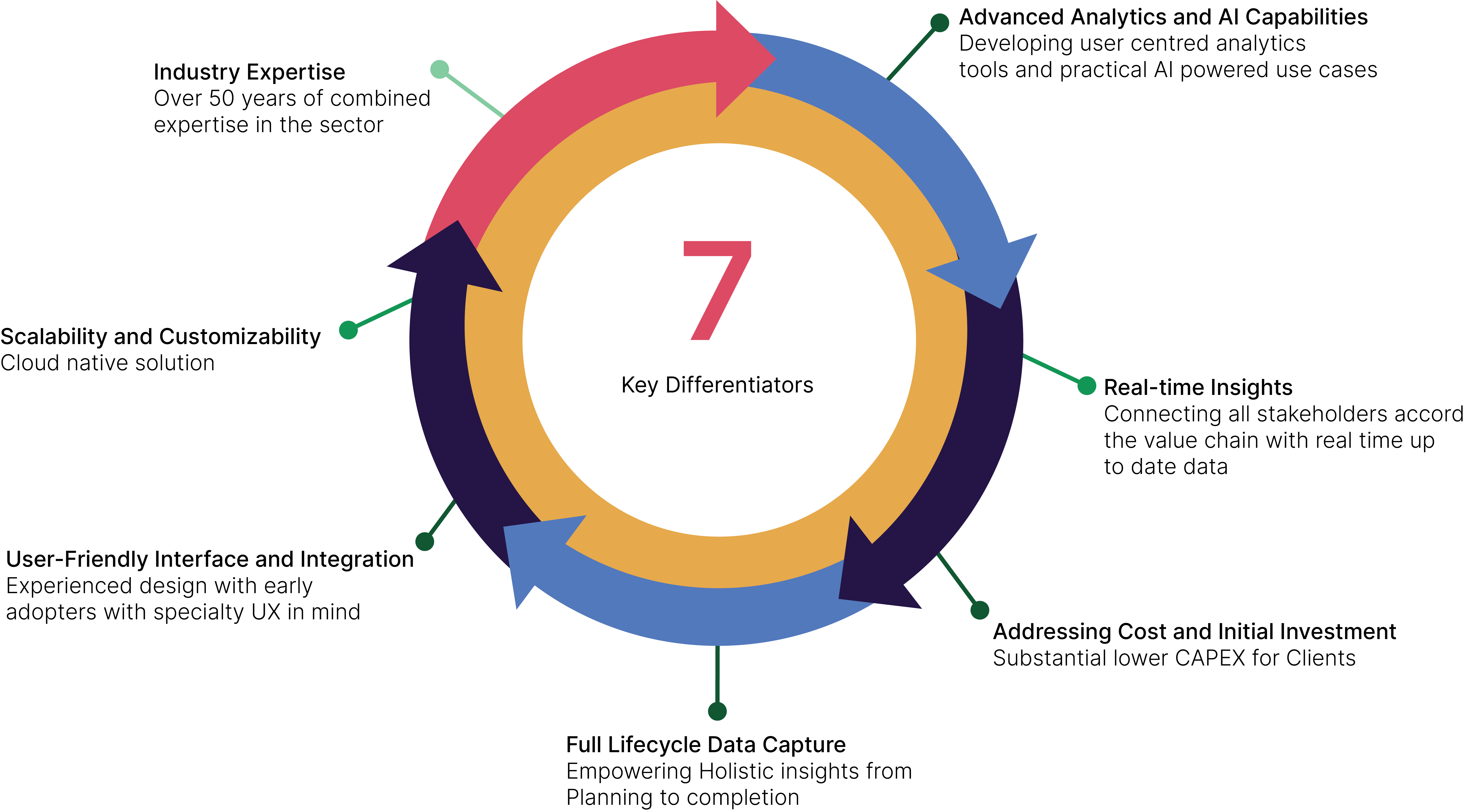

At Konnect3D, we empower the Energy sector with transformative EPC 4.0 digital twin technology. Our mission is to equip clients with powerful yet user-friendly tools for planning and constructing complex projects in the era of EPC 4.0.

Using advanced analytics, AI algorithms, and real-time data integration, we provide unparalleled insights for data-driven decision-making, enabling clients to confidently navigate extreme complexities.

Together with our clients, we revolutionize project planning and execution in the energy sector through simulations and digital twins, driving efficiency, agility, and innovation. Our goal is to shape the future of EPC 4.0, creating lasting positive impact and powering sustainable growth in the industry

Revolutionize Your Oil & Gas Projects with our EPC 4.0

Digital Twin Platform

Seamlessly integrate multiple data types and streamline your workflow.

Efficiency challenges are a major problem for all projects

The project delivery problem

Consistently late and over-budget

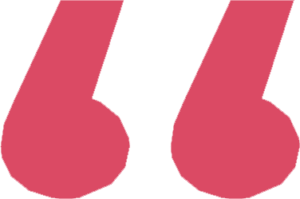

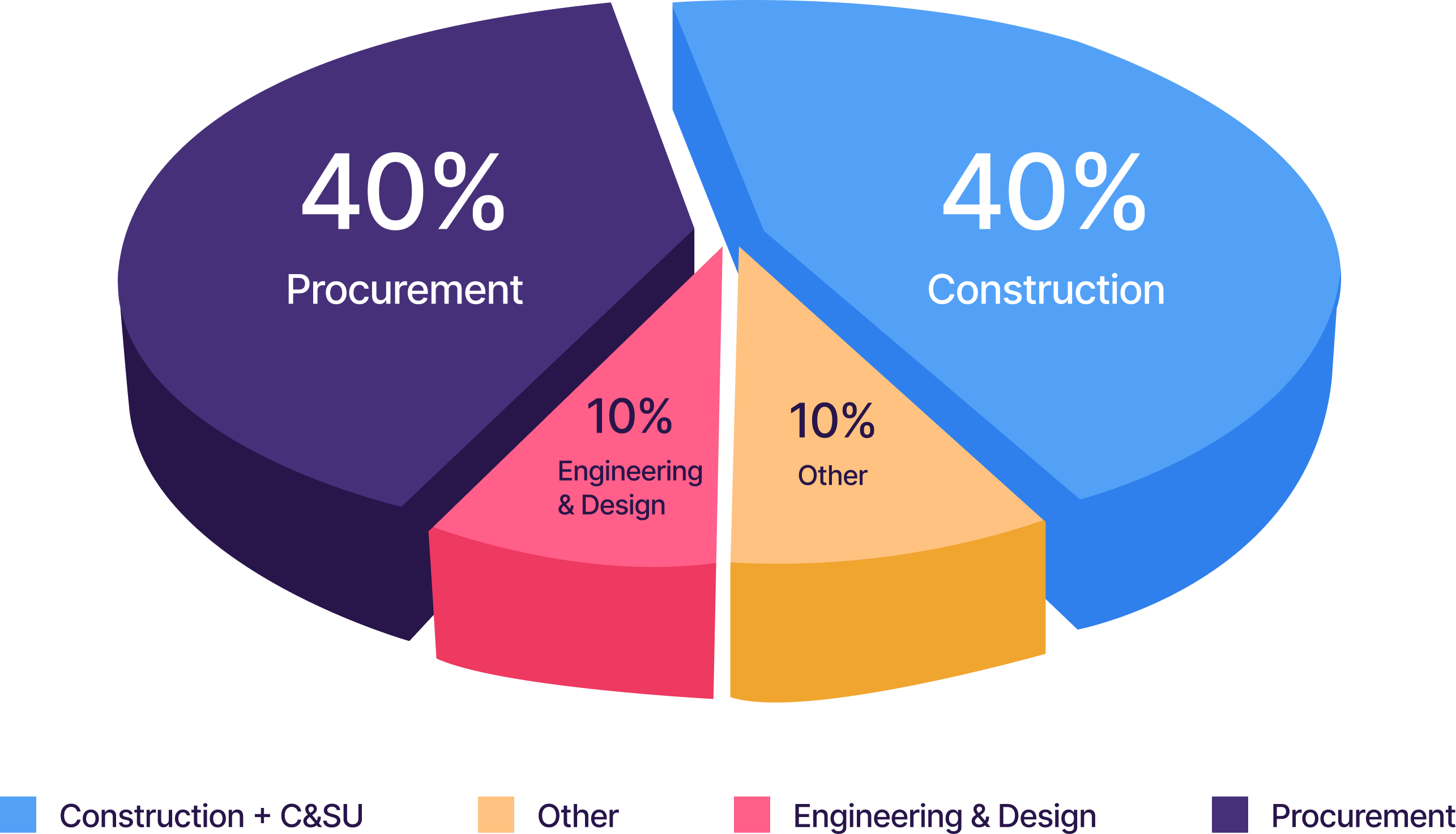

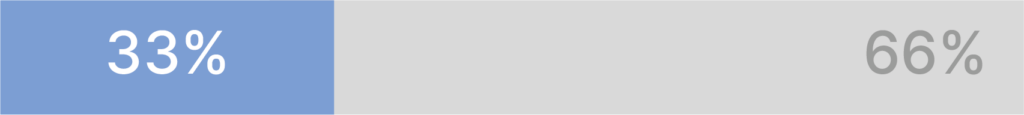

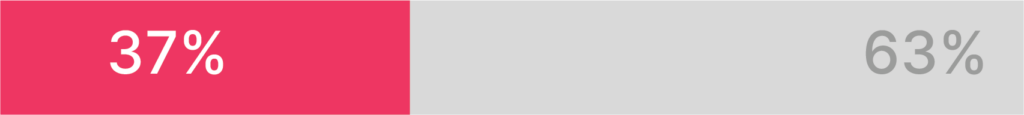

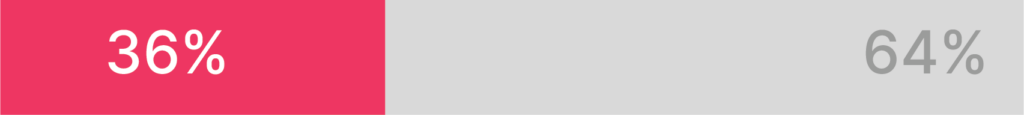

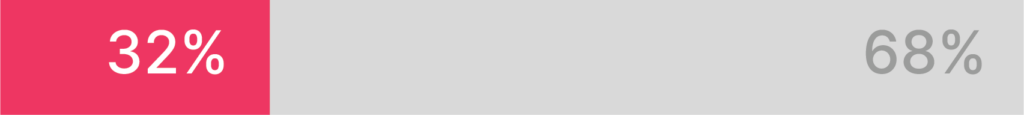

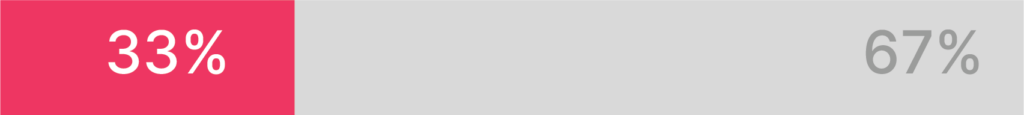

Historical inefficiency Data of projects with budgets > US$1 billion

Source: *McKinsey: The art of project leadership, Sept 2017, IHS Herold Global Projects Database (2017), Basic Materials Database (2012), Megaproject Database (2015)

Cost Overruns: O&G projects experience an average of 40% in cost overruns (Source: Energy Policy Journal, 2020).

Project Delays: Around 75% of upstream oil and gas projects suffer delays (Source: Energy Policy Journal, 2020).

Maintenance and Downtime Costs: Downtime in oil and gas operations can cost up to $260,000 per hour (Source: Aberdeen Group).

Project Delays: Around 75% of upstream oil and gas projects suffer delays (Source: Energy Policy Journal, 2020).

Maintenance and Downtime Costs: Downtime in oil and gas operations can cost up to $260,000 per hour (Source: Aberdeen Group).

The Problem Landscape in a Multi Billion dollars Industry

Profitability and Efficiency Challenges

1

Inefficient Project

Management

With so many moving parts, keeping everything coordinated can be a nightmare. Traditional project management methods often fall short, leading to miscommunication, confusion, and mistakes.

2

Safety Risks

The current planning and construction processes in the oil and gas sector mostly rely on historical data and the expertise of the involved personnel.

3

Inefficient Project

Management

Oil and gas projects come with significant inherent safety risks, including equipment failures, environmental hazards, and human errors.

Data Silos and Collaboration Barriers

4

Limited Data Visibility Across Layers

Creating a unified data source that fosters collaboration across all layers of the organization is a critical challenge. Investors may see this as a priority to drive efficiency and innovation

5

Vertical Data Silos

Breaking down data silos within the company can improve communication and decision-making at all levels, making it an important concern.

6

Lack of Real-time Data Utilization

Current processes are unable to efficiently leverage real-time data from the site and equipment.

“Digital Transformation Barriers in the Oil & Gas Sector”

“The oil and gas industry lags in digital transformation due to resistance, project failures, and stalled initiatives. Existing solutions often demand high expertise and heavy implementations, creating barriers to adoption.”

Why does the Industry need a solution ?

Digital Innovation in Engineering

To Leverage technological Advancements

Digital Twin for Improved Estimates: Utilizing digital twin technology allows for more accurate estimates, faster engineering processes, and better collaboration.

On-Site Issue Management: Digital twin technology can help manage and resolve issues on-site by efficiently transferring information between the site and project management.

Web-Based Tool for Integration: A web-based tool that integrates all project information can greatly enhance the efficiency of EPC projects.

Real-Time Comparison: The technology allows for real-time comparison between the as-built model and the actual construction, enabling efficient changes and adjustments during project execution.

Single Source of Truth: Digital twin technology provides a single source of truth with up-to-date information, enabling good decision-making.

Operational Complexity and Efficiency Optimization

To Maximize Project Management and Efficiency

Increasing Complexity in Projects: The increasing complexity of projects, shorter investment frames, and market instability contribute to difficulties in estimating prices and timelines.

Material Management: Combining digital twin technology with site material management can help avoid idle hours and improve construction sequencing and work breakdowns.

Efficiency in EPC Projects: Utilizing digital twin technology can significantly improve efficiency by consolidating and visualizing various project data in one clear view, eliminating the need for multiple software and reducing conflicts among project members.

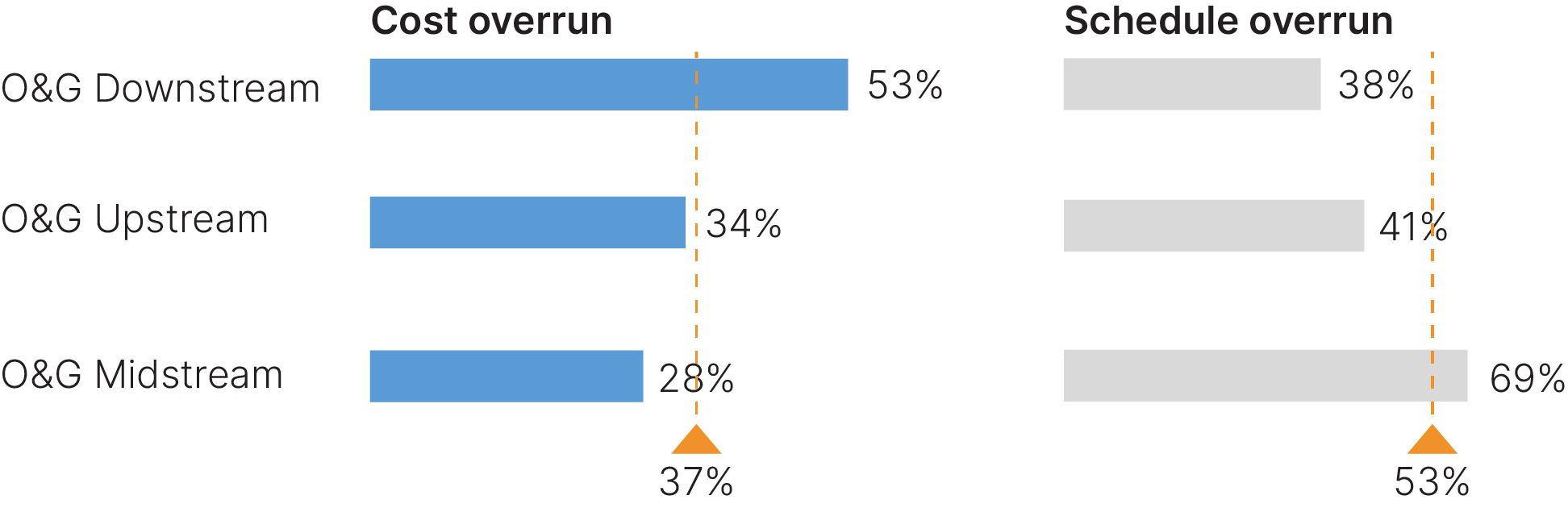

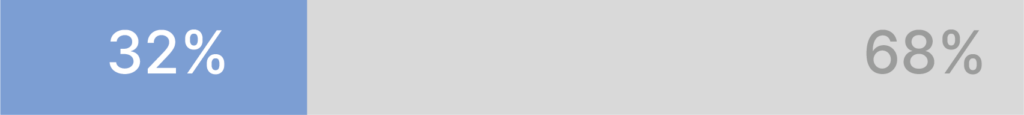

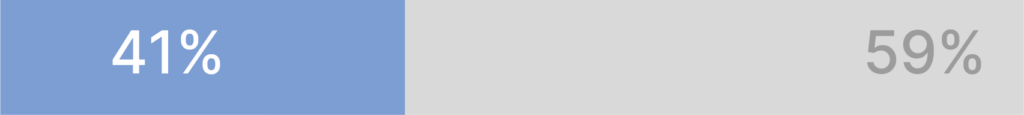

Nine out of ten companies invest significantly in new digital technology. However 2/3rds do not achieve the desired better outcomes

• Strategic failure building the right operating environment and incentives to create a data centric culture.

• Inability to operationalize data and technology for more effective decision- making as well as completion of projects on time and within budgets.

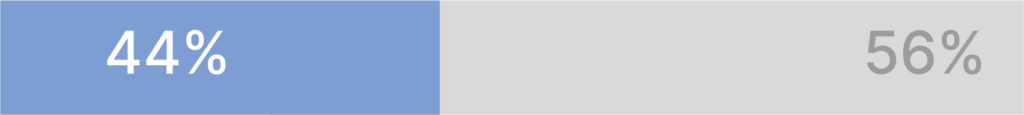

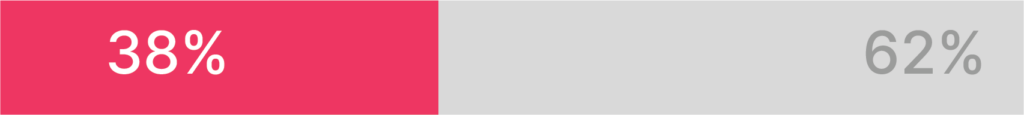

Uneven Gains unrealized across industries

Impact of digital technologies/applications on the most recently completed capital project.

Impact of digital technologies/applications on the most recently completed capital project.

Reduced equipment & material cost

Construction productivity

improved operating margin

improved risk assessment capability

Ease of access to skilled labor

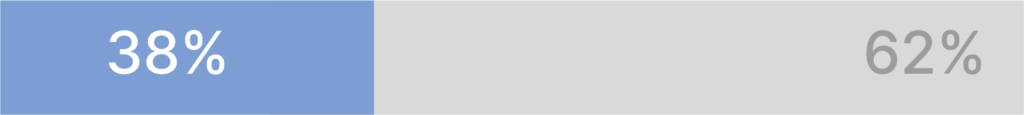

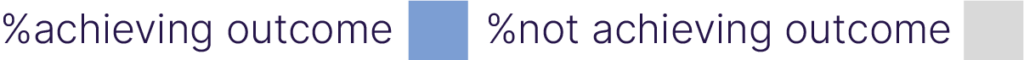

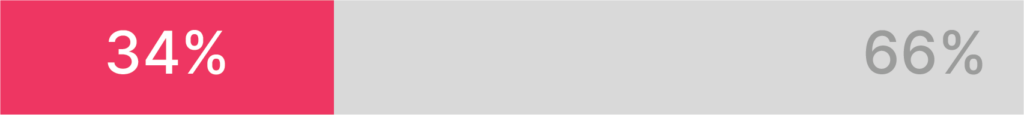

Struggling for better outcomes

Impact of digital technologies/applications on the most recently completed capital project.

Impact of digital technologies/applications on the most recently completed capital project.

Reduced equipment & material cost

Construction productivity

On-time completion rate

Improved returns on capital employed

Reduced construction accidents and HSE incidents

Better people retention

Konnect3D presents the next generation EPC Data Modelization tools, finally putting the proactive decision power in the hands of the industry

• Asset Owners

• EPC Contractors & Vendors

• Yard Operators

• Fabricators

• EPC Contractors & Vendors

• Yard Operators

• Fabricators

Through advanced analytics and machine learning, our solution will predict potential issues before they arise, allowing you to make proactive decisions that save time, money, and ensure safety and facilitate immediate response to any project change and teams workload.

Saber Belghith, Founder

• A next generation data-sharing infrastructure and capability platform.

• A digital re-invention of the strategic and operating network of capital projects in Energy.

• Combining the decision-making power of data and analytics with the ingenuity of human collaboration.

• A digital re-invention of the strategic and operating network of capital projects in Energy.

• Combining the decision-making power of data and analytics with the ingenuity of human collaboration.

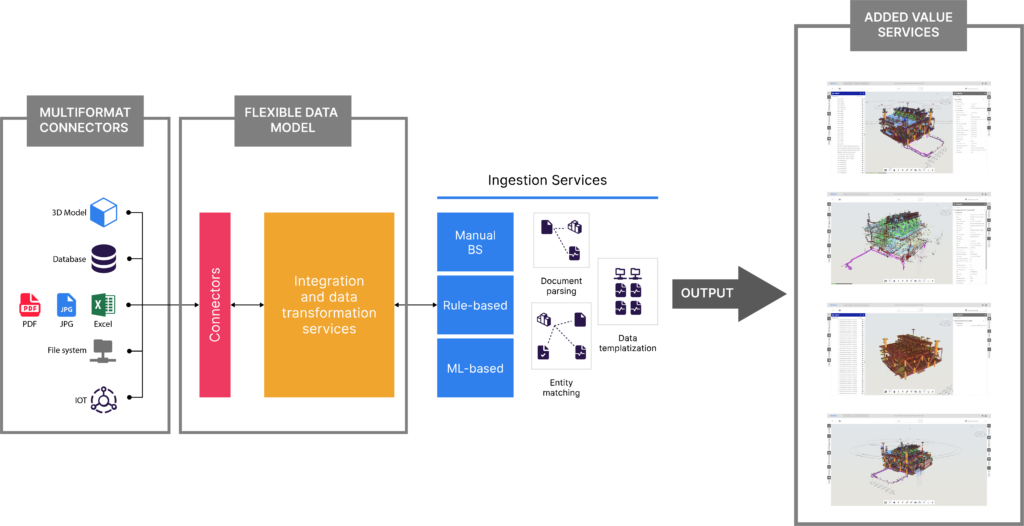

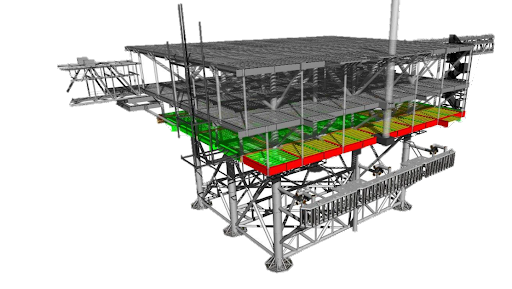

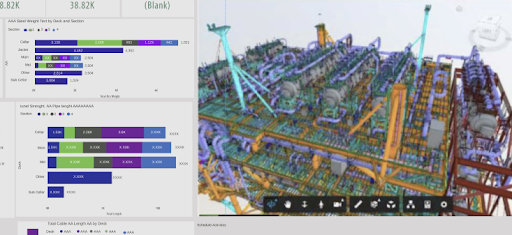

Unlocking value from data created in diverse formats allowing teams to work on live data throughout the construction process

How does it work ?

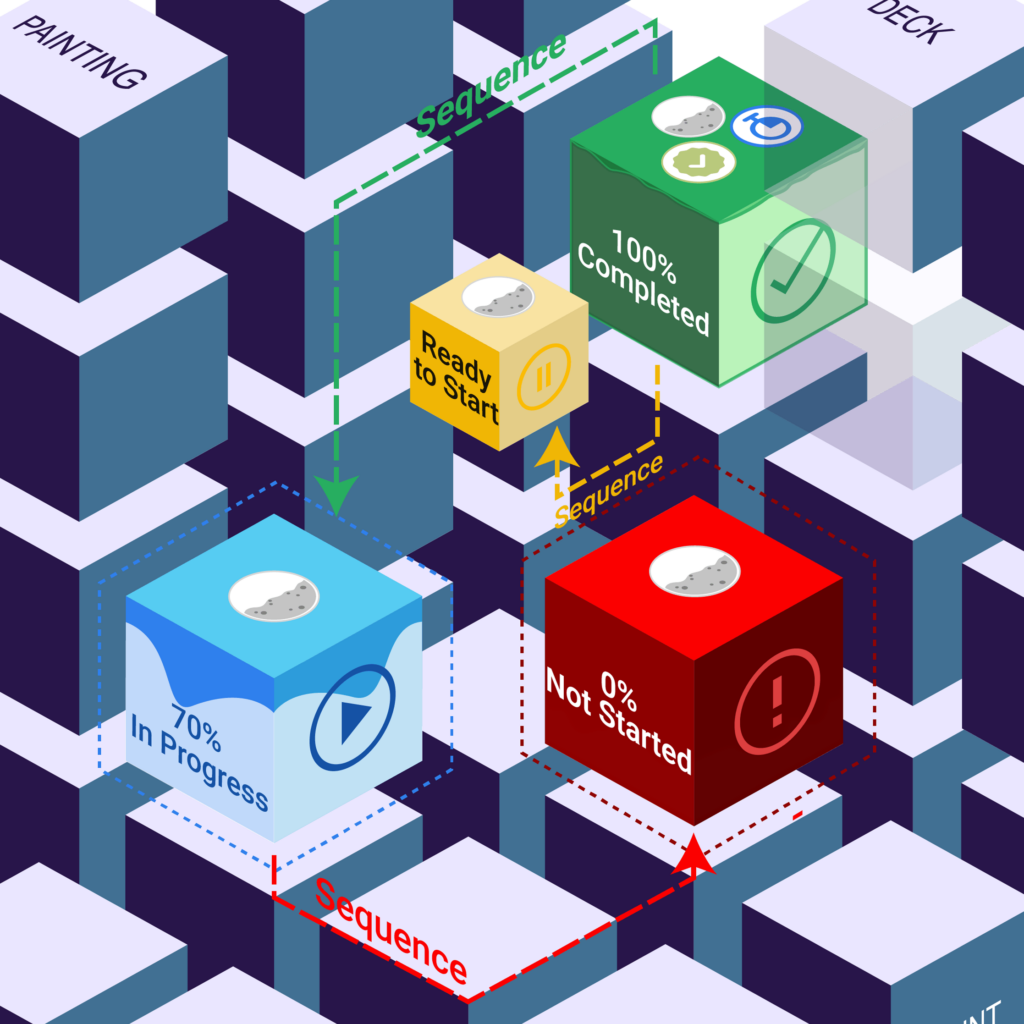

Not Ready to Start

Ready to Start

Started

Progress

Completed

Quality

Completion

Main Functionalities

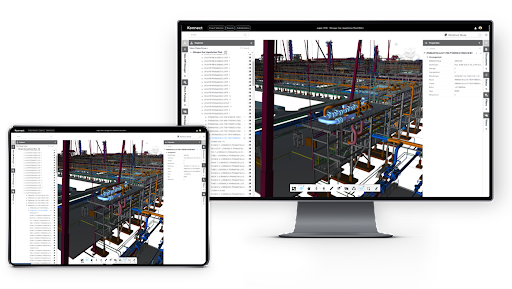

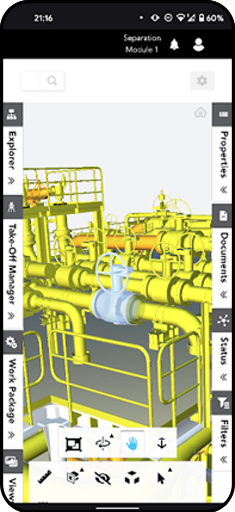

Accessibility and Compatibility

• Access from any device on a web browser (Chrome, Edge, Firefox, Safari)

• Project and model portfolio, accessible by all project members

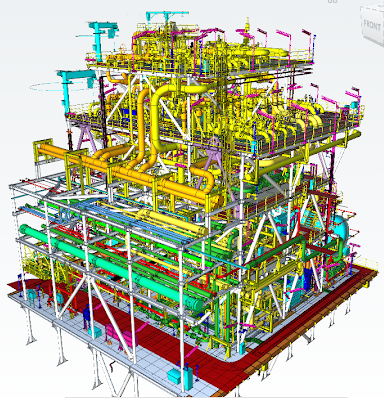

Model Management and Exploration

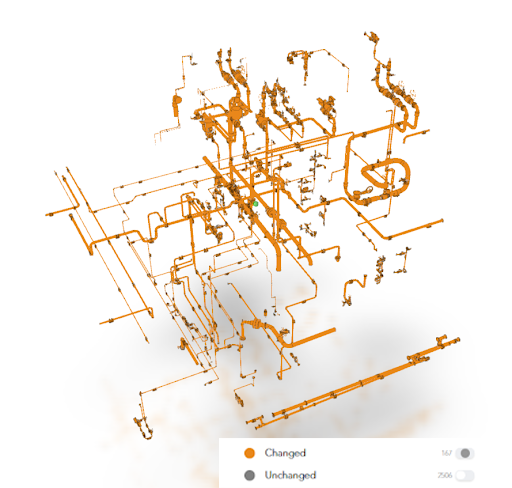

• Automatic 3D models conversion and versioning

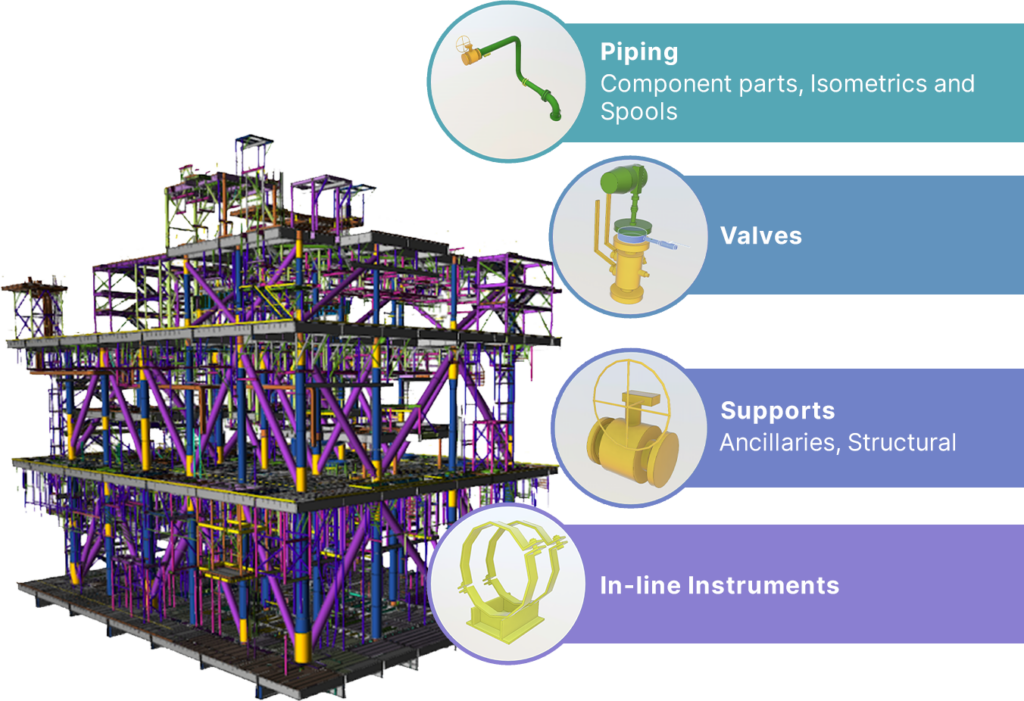

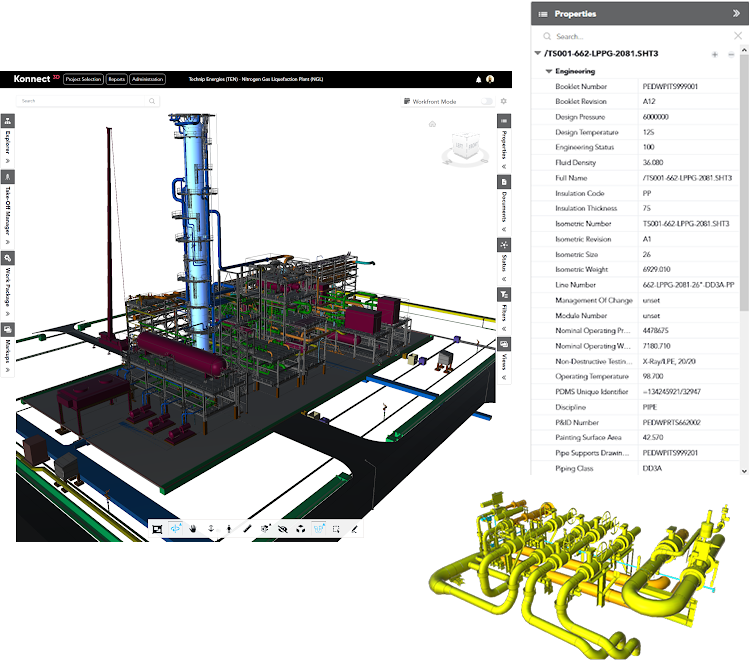

• Construction 3D model viewer with Piping Spools, Assembly Marks, Cable trays, Valves, Instruments …

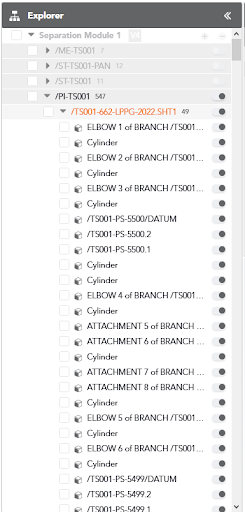

• Intelligent model explorer, hierarchy, grouping

• Conditioned properties, calculated attributes

• Status visualization of the EPC progress

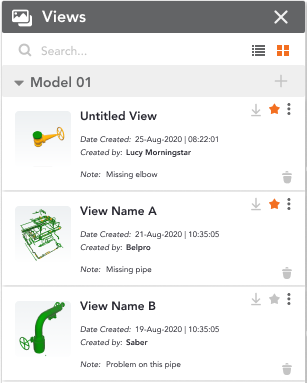

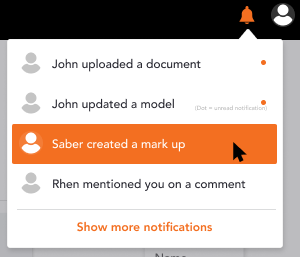

• Collaboration with 2D Markups and Saved Views

Project Organization and Analytics

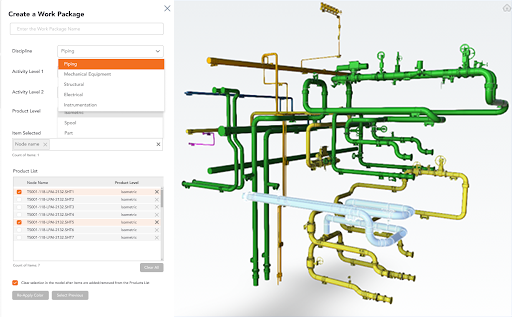

• Work Package Manager

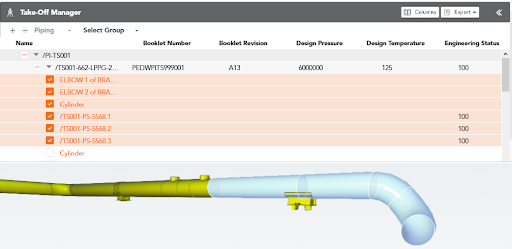

• Take Off Manager

• Powerful and fast search features

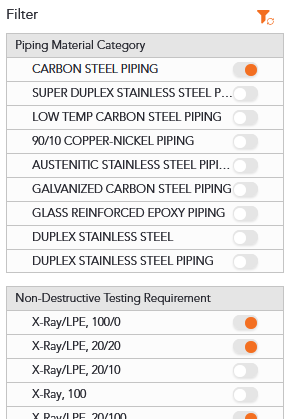

• Filters and groups by any attribute

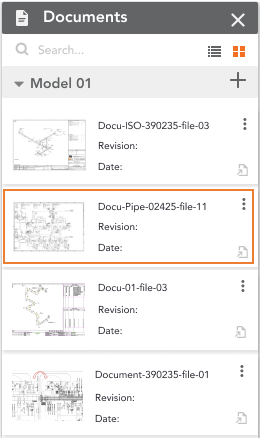

• Documents to Tag viewer

• Import / enrich data to Tag (planning, progress, …)

• Business Intelligence and Reports

• Access from any device on a web browser (Chrome, Edge, Firefox, Safari)

• Project and model portfolio, accessible by all project members

Model Management and Exploration

• Automatic 3D models conversion and versioning

• Construction 3D model viewer with Piping Spools, Assembly Marks, Cable trays, Valves, Instruments …

• Intelligent model explorer, hierarchy, grouping

• Conditioned properties, calculated attributes

• Status visualization of the EPC progress

• Collaboration with 2D Markups and Saved Views

Project Organization and Analytics

• Work Package Manager

• Take Off Manager

• Powerful and fast search features

• Filters and groups by any attribute

• Documents to Tag viewer

• Import / enrich data to Tag (planning, progress, …)

• Business Intelligence and Reports

Stakeholder Engagement

Team Coordination

Transparency & Accountability

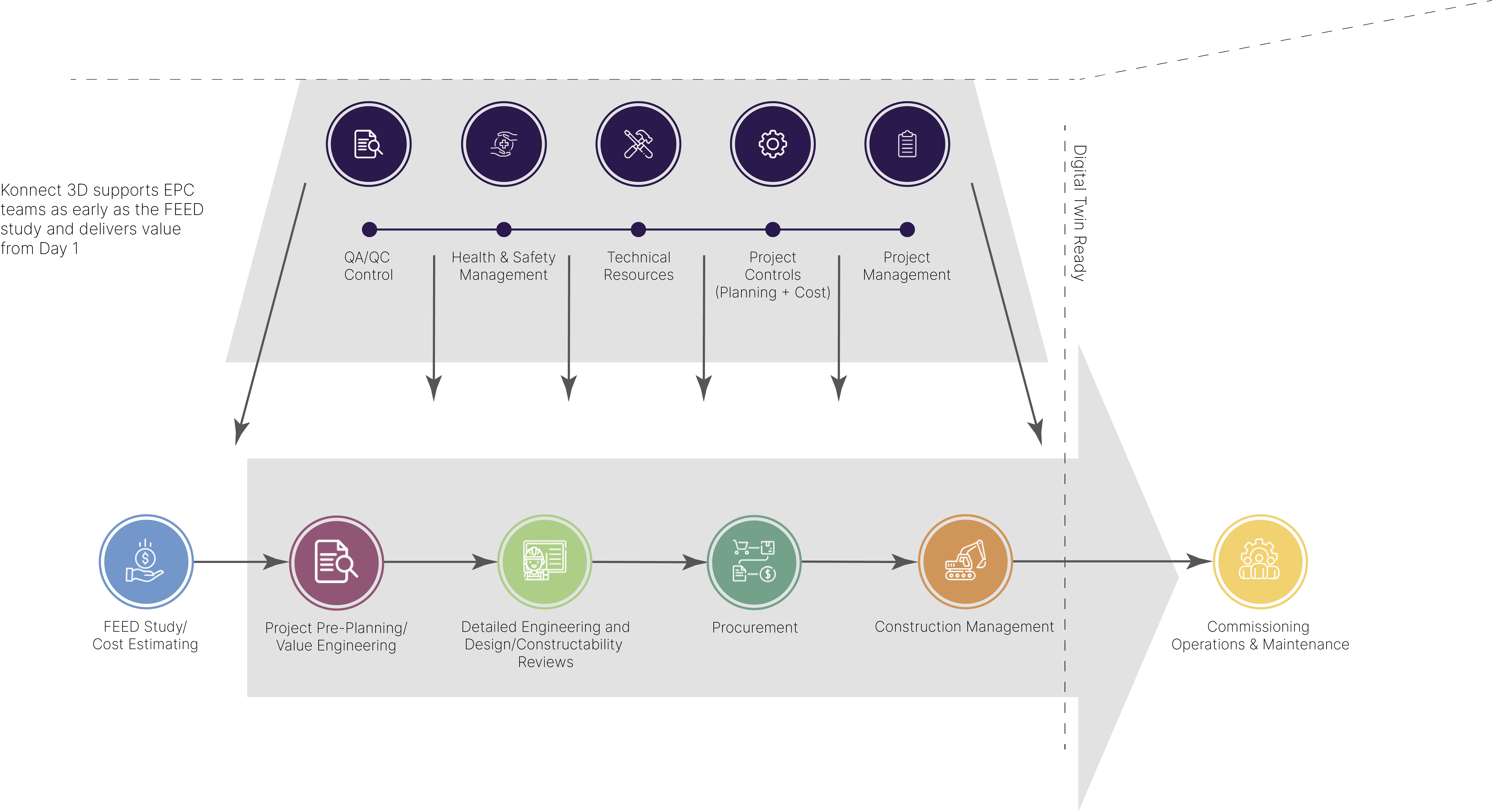

Capabilities through the EPC lifecycle

3D Models

Process Data & Engineering

Material Traceability Material Reservation

Material Allocation Fabrication Assembly/Erection

Pressure tests Pre/Commissioning

Gather

Generate

Communicate

Analyze

Produce

Early Stage Capabilities

• All disciplines tagged items in all engineering disciplines such as piping, valves, supports, in-line instruments properties in a data-centric 3D environment

• Incorporate engineering drawings / specifications documents

viewer, revision, and status

• Identify systems, P&ID, Line, Services, Isometrics, Spools, Welds (erection, fabrication), and Parts, including erection materials

• Load turn‐over systems and load/create test package extents

Work Package Definition and Management

• Define Engineering, Procurement, or Construction work package scope

• Generate work package reports

• Visualize status reporting Engineering, Procurement, Construction

• Create reports as material take-off, with current status, per work package

• Update work packages through engineering model change management

Project Monitoring and Reporting

• Visually monitor external fabrication status and delivery

• Identify material availability status, material allocation

• Identify systems, test packages, material take‐off items

• Visualize status for overall project reporting Engineering,

Procurement, Construction

• Virtual walk-down and review of system/test‐pack scope

• Visually monitor QA / QC

• Visually monitor test package completion status

• Produce test package expediting reports

• All disciplines tagged items in all engineering disciplines such as piping, valves, supports, in-line instruments properties in a data-centric 3D environment

• Incorporate engineering drawings / specifications documents

viewer, revision, and status

• Identify systems, P&ID, Line, Services, Isometrics, Spools, Welds (erection, fabrication), and Parts, including erection materials

• Load turn‐over systems and load/create test package extents

Work Package Definition and Management

• Define Engineering, Procurement, or Construction work package scope

• Generate work package reports

• Visualize status reporting Engineering, Procurement, Construction

• Create reports as material take-off, with current status, per work package

• Update work packages through engineering model change management

Project Monitoring and Reporting

• Visually monitor external fabrication status and delivery

• Identify material availability status, material allocation

• Identify systems, test packages, material take‐off items

• Visualize status for overall project reporting Engineering,

Procurement, Construction

• Virtual walk-down and review of system/test‐pack scope

• Visually monitor QA / QC

• Visually monitor test package completion status

• Produce test package expediting reports

Konnect 3D harvest the true power of Data Modelization from inception, throughout construction and post delivery

The Konnect3D “Dynamic Twin Power”.

Unique differentiators aligned with Strategic Objectives

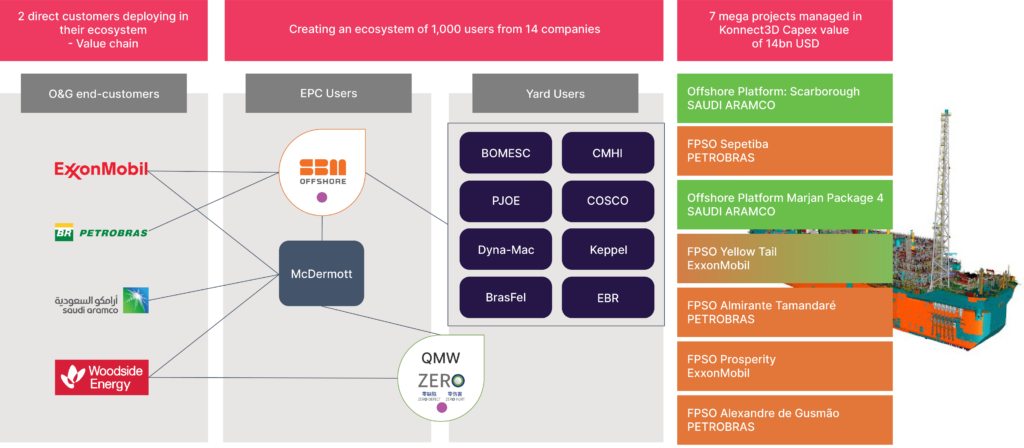

Konnect3D direct customers orchestrate a group of users on common projects, invoking and catalyzing Viral collaborationacross ecosystems

Since 2021, Konnect3D was deployed on 7 projects with a USD14bn Capex value, achieving significant productivity improvement and cost savings

Konnect3D is one of the greatest and most exciting opportunity to improve what we do and land construction into the 21st century

Karim Bouab, SBM Offshore Construction Director

K3D interfaces with a large number of our systems, both internal and external, and is able to act as a cornerstone for system integration, K3D plays a critical role in getting all the data integrated, analysed and presented

Li Qiuzhe, General Manager | ZERO, Qingdao McDermott Wuchuan

Project case studies from SBM Offshore (in 5 active projects) shows a 16% Productivity improvement and average $2mn saved per project

16% SBM productivity improvement

Saved up to $2mn per project

• $700K savings / 32 days on critical path: Piping Fabrication and Erection activities

• $500K savings in claim reduction from Engineering delays and reworks

• $800K reduction of Subcontractors rate cards, FOC access the application, ie. improvement in planning and execution (+material and labor productivity)

• $500K savings in claim reduction from Engineering delays and reworks

• $800K reduction of Subcontractors rate cards, FOC access the application, ie. improvement in planning and execution (+material and labor productivity)

The application is deployed on 5 FPSO projects and 1 renewable energy project.

Web-based, Device

Responsive, User Friendly

Web-based, Device

Responsive, User Friendly

Web-based, Device

Responsive, User Friendly

Web-based, Device

Responsive, User Friendly

Onboarding / Login page

Web-based, Device

Responsive, User Friendly

Engineering Data

Supply Chain

Web-based, Real-Time, Collaborative project status in 3D

• Engineering Model Model with all attributes

• Supply-Chain with purchase status,

ETA, ROS dates

• Construction Status

• Supply-Chain with purchase status,

ETA, ROS dates

• Construction Status

Interactive Status Visualization (current & lookahead)

Take-Off Management

Construction Work Packages definition

Yards

Access the full Engineering Hierarchy enriched with Supply Chain, Fabrication, Construction and Commissioning/Startup data

Search & Filter instantly from

E, P or C attributes

Friendly in-browser interactive 3D Model

Isolate complex areas for fine-analysis

Work Package, Documents and Views

Easy “Point & Click” Work Packages creation

Tag to Documents connected to the 3D Model

Capture, Save and Share the current 3D View

Work Package, Documents and Views

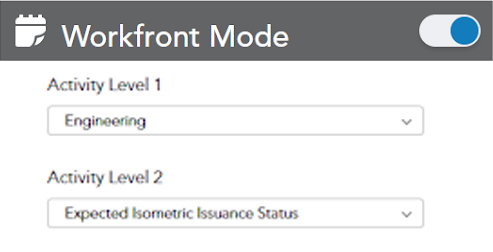

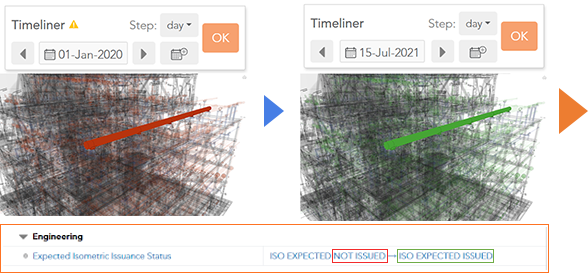

Visualize project status at different dates

Past, Present and Future dates navigation with the Timeliner

Past, Present and Future dates navigation with the Timeliner

Visualize, understand, debottleneck from real-time status

Query, Aggregate and export key project data

Report on Key Project Metrics

Collaborate with project members from all companies

Contact our team

Embark on a transformative journey with Konnect3D’s Digital Twin platform, designed to navigate the complexities of business development in the oil and gas sector. Explore our solutions and unlock the potential of digital innovation for your projects!